- Out-of-Stock

PRICE CONCERNS 1 PC SOCKET

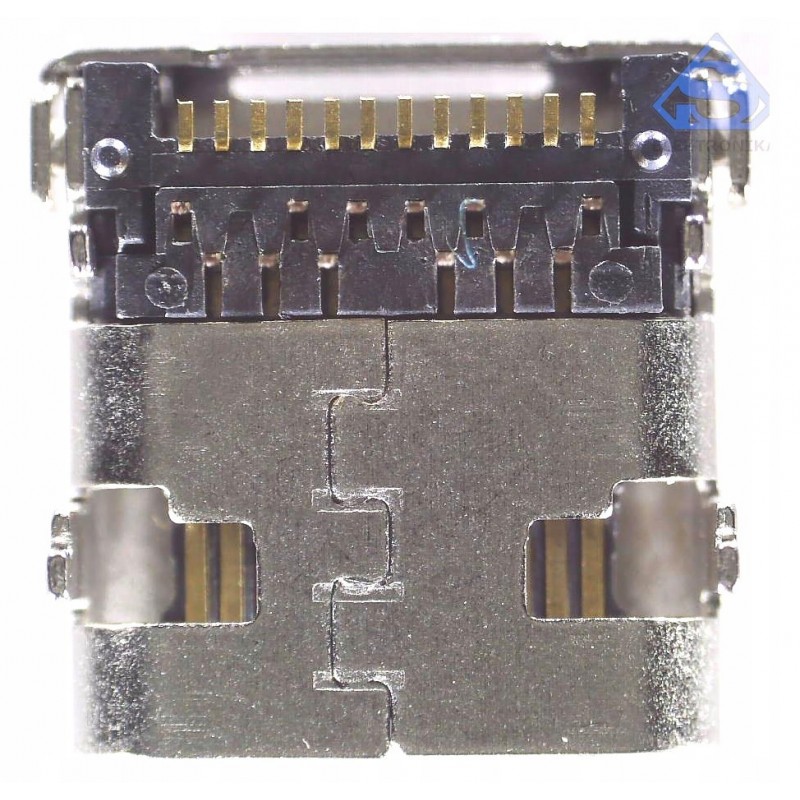

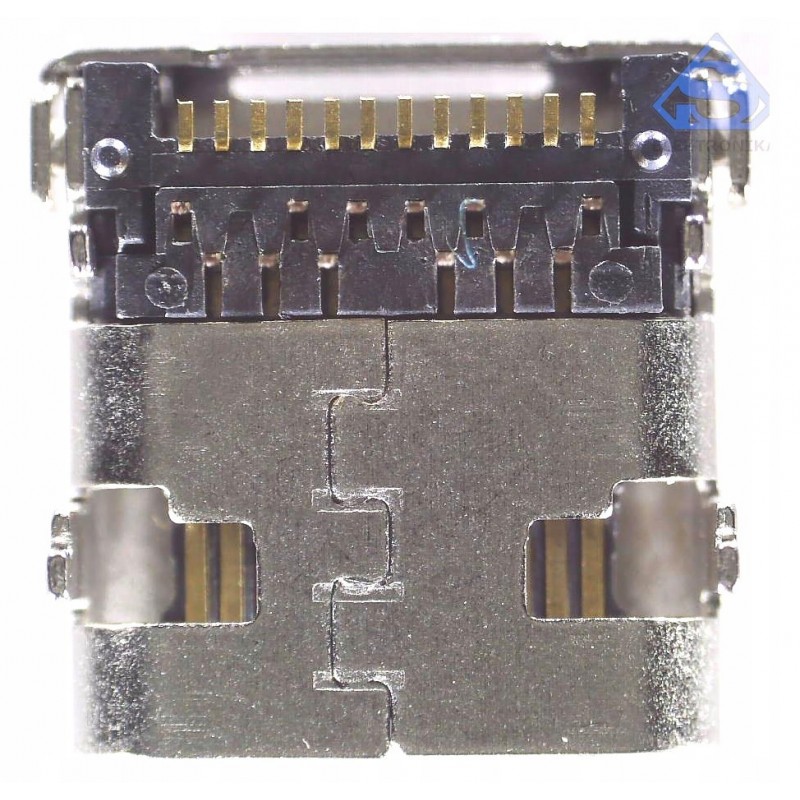

We also offer other USB C and Micro sockets for installation

The product was placed on the market within the EU before December 13, 2024.

High Voltage and Current – This component can operate at high voltages and currents, posing a risk of electric shock. Pay attention to the maximum voltage and current values, as well as appropriate markings indicating these limits.

Caution During Installation – Ensure that the components are correctly mounted in the circuit, as improper connections can lead to overheating, damage, or fire.

Corrosion – Avoid contact with moisture: Fastening components should be protected from prolonged exposure to moisture or aggressive chemicals that can cause corrosion.

Use of protective coatings – Ensure that the components are protected with an anti-corrosion coating suitable for the operating environment (e.g., galvanizing, epoxy coatings). Regular maintenance: Inspect components for signs of corrosion and replace them as needed.

Mechanical damage – Do not exceed the maximum tightening torque: Over-tightening can damage the thread or weaken the fastening components. Use tools with the correct torque rating.

Avoid dynamic loads beyond specifications – Bolts and screws should be used according to their intended purpose, especially in applications exposed to vibrations or impacts.

Pre-use inspection – Before installation, check components for deformation, cracks, or other damage.

Improper use – Ensure you are using fastening components of the correct size, material, and strength class for the given application.

Do not use damaged components – Bolts, screws, and washers with visible mechanical damage or corrosion should be immediately replaced.

Avoid improper assembly – Ensure proper alignment and compression to avoid stresses in the fastening material.

Use of appropriate tools – Use tools that meet specifications for assembly and disassembly (e.g., torque wrenches).

Swallowing Hazard – Small fastening components, such as screws, nuts, or washers, can pose a choking or swallowing hazard, especially for children. They should be stored in a place out of reach of children.

Spreading of Small Components – These components can pose a tripping or loss hazard during work. They should be stored in containers that prevent spillage.

You might also like