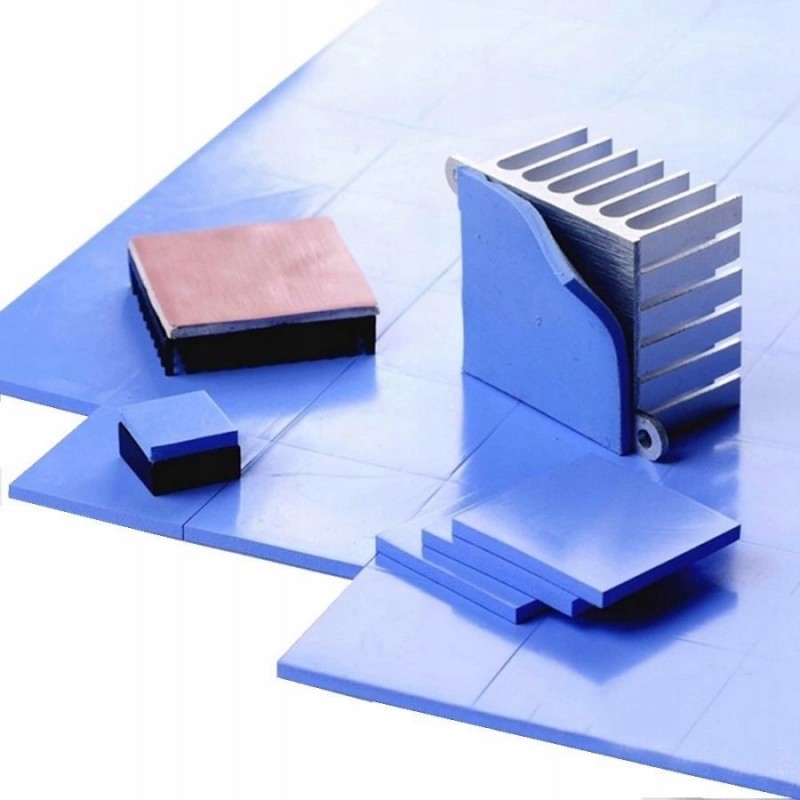

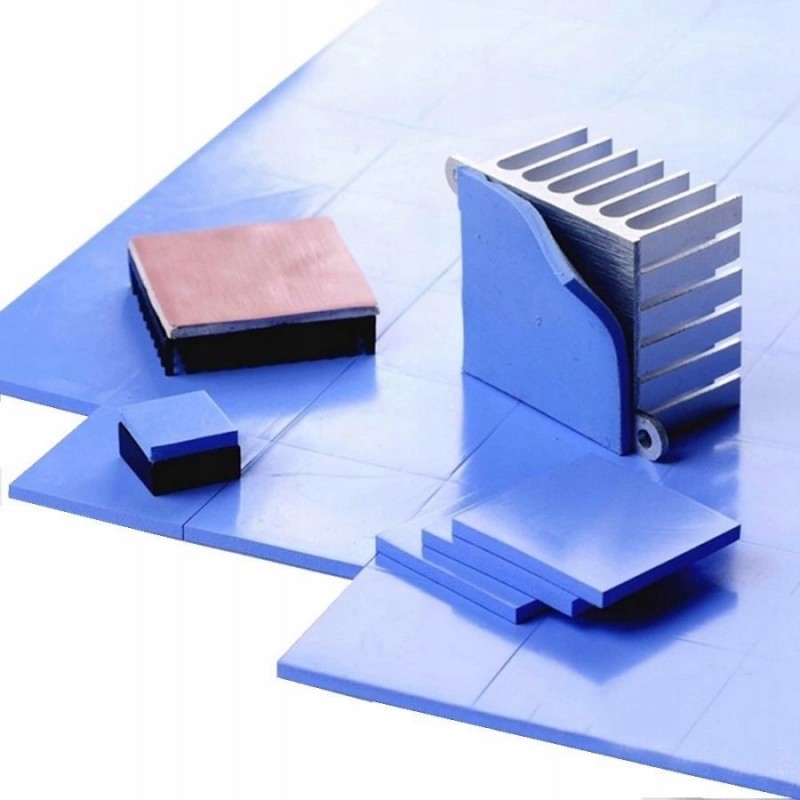

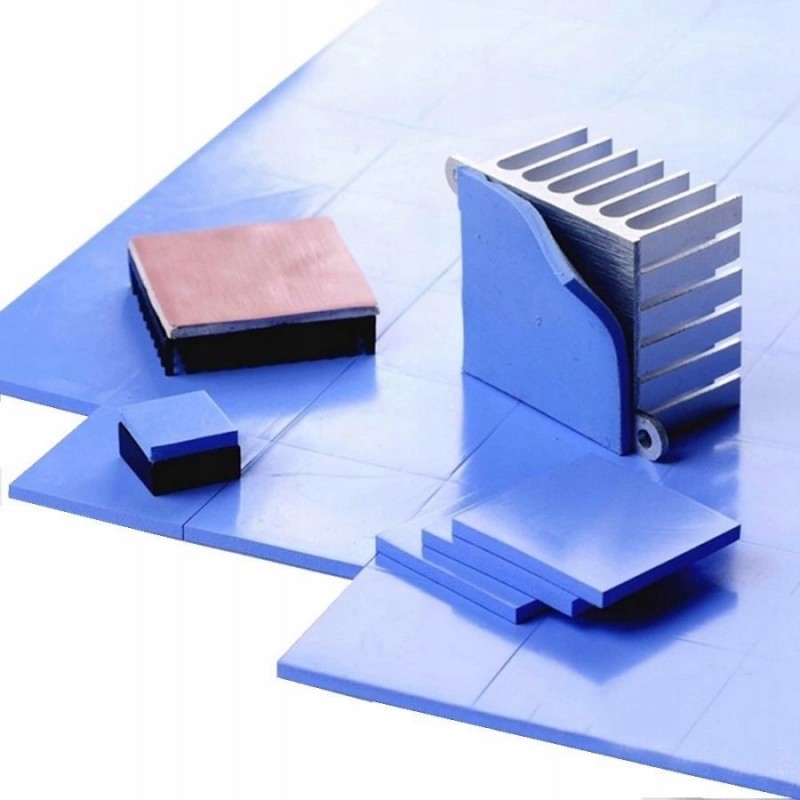

1x Thermopad 10x10x0.5 mm TO220, TO252, TO263

Introducing our top-of-the-line 10x10x0.5 thermally conductive pad, designed to meet the demands of your electronic needs. This remarkable product boasts a meticulously engineered thermowell, measuring at 10x10x0.5mm, ensuring optimal performance in heat dissipation. With its impressive thermal conductivity ranging from 1.2W to 2.0W, this pad effectively transfers heat away from your sensitive components, maximizing their lifespan and enhancing overall functionality.

Our 10x10x0.5 thermally conductive pad is crafted to withstand extreme temperatures, with an impressive temperature range of -40°C to 220°C. This exceptional versatility guarantees its reliability and stability in various operating conditions. Additionally, this pad exhibits remarkable voltage resistance, surpassing 4kV, ensuring the utmost safety for your valuable electronic enclosures such as TO220, TO252, TO263, and more. Its compatibility with a wide range of enclosures makes it a convenient and versatile choice for your electronic projects.

What sets our thermally conductive pad apart is its low viscosity, specifically designed for easy application and secure attachment to your screw-on components. This user-friendly feature ensures a hassle-free installation process, allowing you to focus on your electronic projects with ease.

All components of our 10x10x0.5 thermally conductive pad undergo rigorous testing procedures to guarantee their quality and reliability. We pride ourselves on delivering products that are thoroughly validated based on both internal and customer feedback, because your satisfaction is our ultimate priority.

Invest in the exceptional performance and peace of mind that our 10x10x0.5 thermally conductive pad offers. Enhance the longevity and efficiency of your electronic devices today by adding this remarkable product to your cart. Experience the difference for yourself!

The product was placed on the market within the EU before December 13, 2024.

High Voltage and Current – This component can operate at high voltages and currents, posing a risk of electric shock. Pay attention to the maximum voltage and current values, as well as appropriate markings indicating these limits.

Caution During Installation – Ensure that the components are correctly mounted in the circuit, as improper connections can lead to overheating, damage, or fire.

Corrosion – Avoid contact with moisture: Fastening components should be protected from prolonged exposure to moisture or aggressive chemicals that can cause corrosion.

Use of protective coatings – Ensure that the components are protected with an anti-corrosion coating suitable for the operating environment (e.g., galvanizing, epoxy coatings). Regular maintenance: Inspect components for signs of corrosion and replace them as needed.

Mechanical damage – Do not exceed the maximum tightening torque: Over-tightening can damage the thread or weaken the fastening components. Use tools with the correct torque rating.

Avoid dynamic loads beyond specifications – Bolts and screws should be used according to their intended purpose, especially in applications exposed to vibrations or impacts.

Pre-use inspection – Before installation, check components for deformation, cracks, or other damage.

Improper use – Ensure you are using fastening components of the correct size, material, and strength class for the given application.

Do not use damaged components – Bolts, screws, and washers with visible mechanical damage or corrosion should be immediately replaced.

Avoid improper assembly – Ensure proper alignment and compression to avoid stresses in the fastening material.

Use of appropriate tools – Use tools that meet specifications for assembly and disassembly (e.g., torque wrenches).

Swallowing Hazard – Small fastening components, such as screws, nuts, or washers, can pose a choking or swallowing hazard, especially for children. They should be stored in a place out of reach of children.

Spreading of Small Components – These components can pose a tripping or loss hazard during work. They should be stored in containers that prevent spillage.

| Manufacturer (Private Label) (EU) 2023/988 (GPSR) | |

|---|---|

| Name: | Superelektronika sp. z o.o. |

| Address: | ul. gen. K. Sosnkowskiego 26/83 05-300 Mińsk Mazowiecki, Poland |

| E-mail: | sklep@superelektronika.pl |

| Responsible Person (EU) 2023/988 (GPSR) | |

| Full Name: | Radosław Jaromin |

| Address: | Arynów 46A 05-300 Mińsk Mazowiecki, Poland |

| E-mail: | radoslaw.jaromin@gmail.com |

You might also like